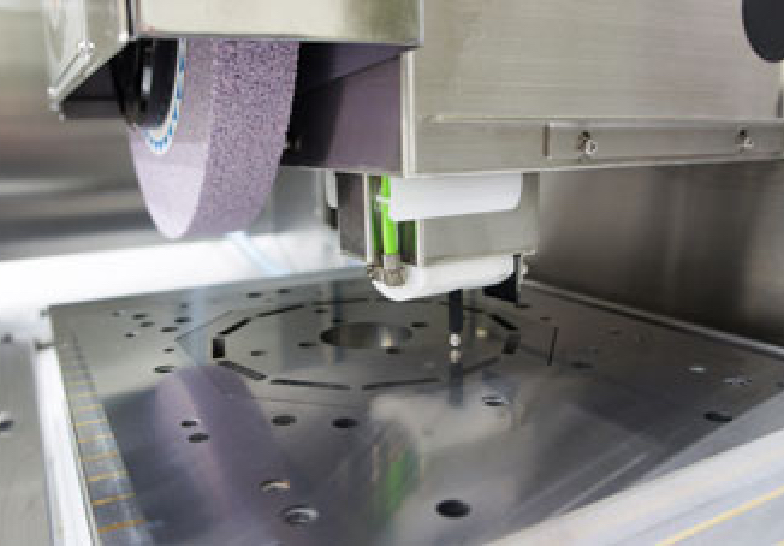

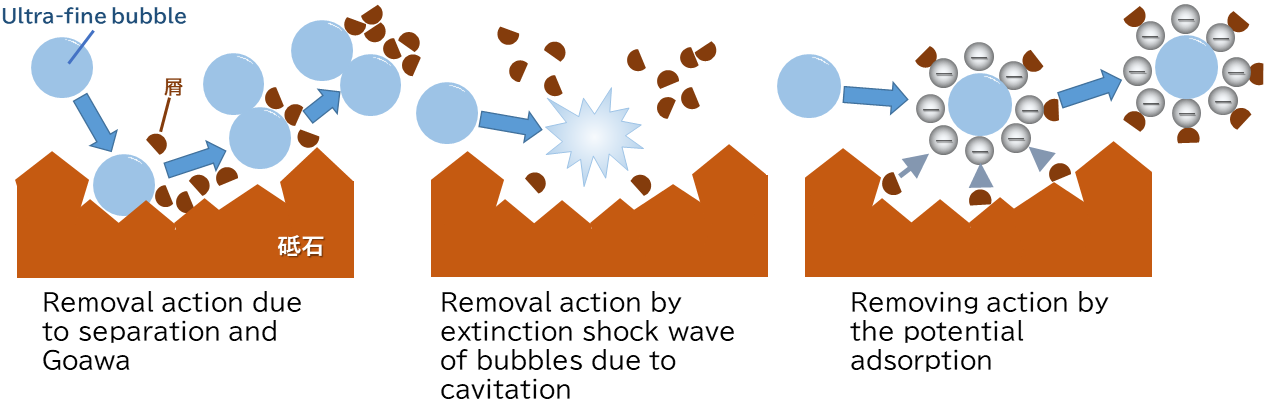

KURODA has experience and know-how as surface grinding manufacturer more than 65 years.Considering customer voice, KURODA suggest automatic grinding machine.Only KURODA can support safty, non-stress and stable grinding.

Suggestions from the processing to accuracy evaluation and measurement automation system by the robot transport.

Our company core competence, precision processing technology and precision measurement technology, makes it possible to intorduce an example of the automation utilized by the robot.

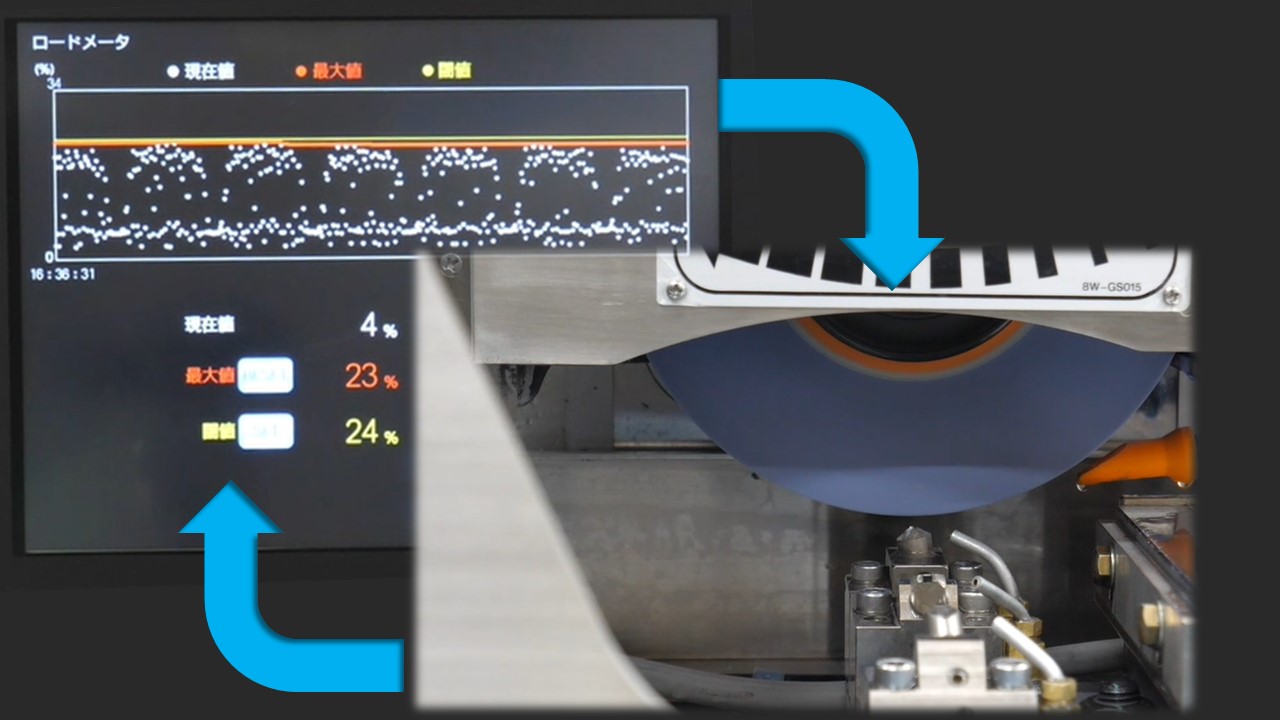

<Output Example>

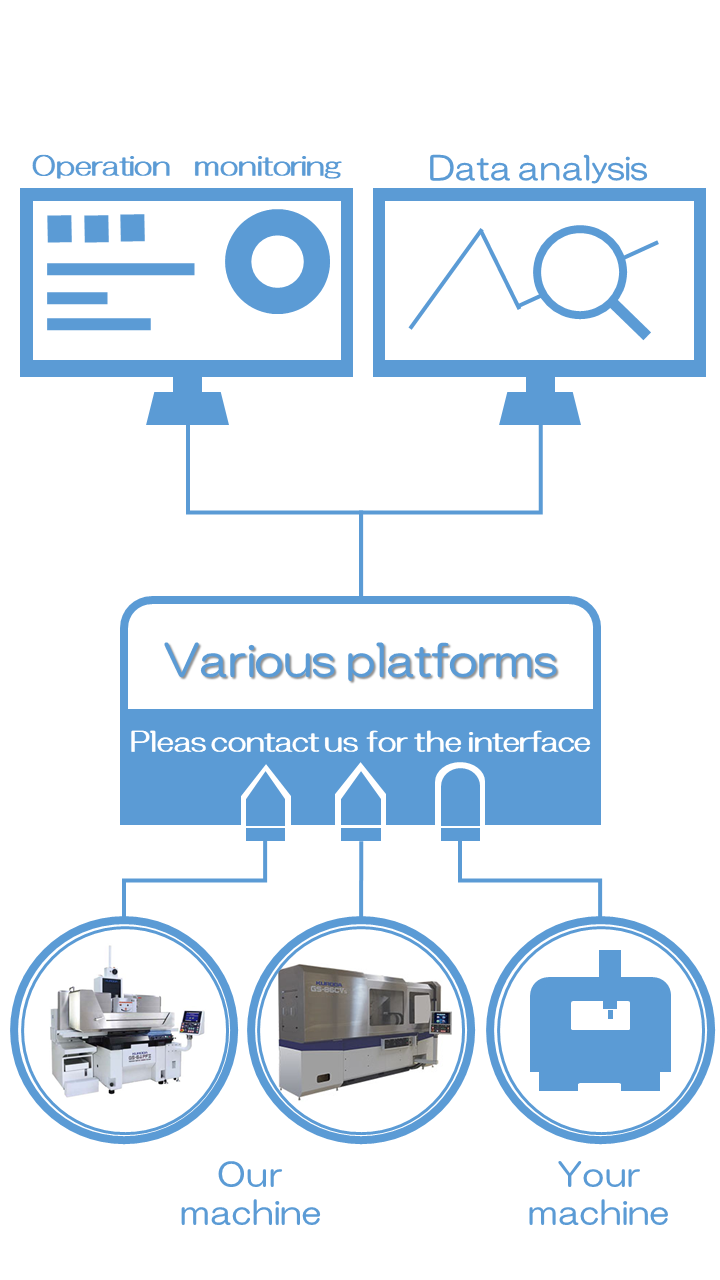

※ Connect operation and output content varies from IoT pratformer and grinding machine models.