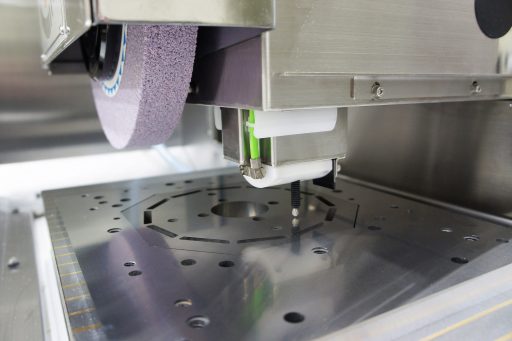

Manual grinding operation is easy to operate and fully automatic setting is also very easy.The operation switch, handle layout and the touch panel is excellent operability and visibility.

|

|

|

|

|

|

|

|

| Unit | GS-45V/VR | GS-45V/VRs | ||

| Working surface of the table(L x W ) | mm | 500×150 | ||

| MAX. traverse of the table (long x Cross ) |

mm | 580×200 | ||

| Distance from table top surface to bottom surface of wheel | mm | 40 ~ 390 | ||

| Standard magnetic chuck size | Flat type | mm | electromagnetic 450×150×70 | |

| Tilting type | mm | electromagnetic 380×110×125 | ||

| Max.mass of workpiece | kg | 70 | ||

| Longitudinal feed rate | m/min | 1~40 | ||

| Saddle cross feed | Feed per revolution of handwheel | mm | 0.01 / 0.1 / 1 .0 / 5.0 | |

| Feed per graduation of dial | mm | 0.0001 /0.001 /0.01 /0.05 | ||

| Cross auto infeed | Step feed | mm | 0.1 ~ 50Optional setting | |

| Continuous feed rate | mm/min | 1~1000 | ||

| Vertcal feed speed | mm/min | 500 | ||

| Wheel dimention(D x W xB) | mm | φ180×6~25×31.75 | ||

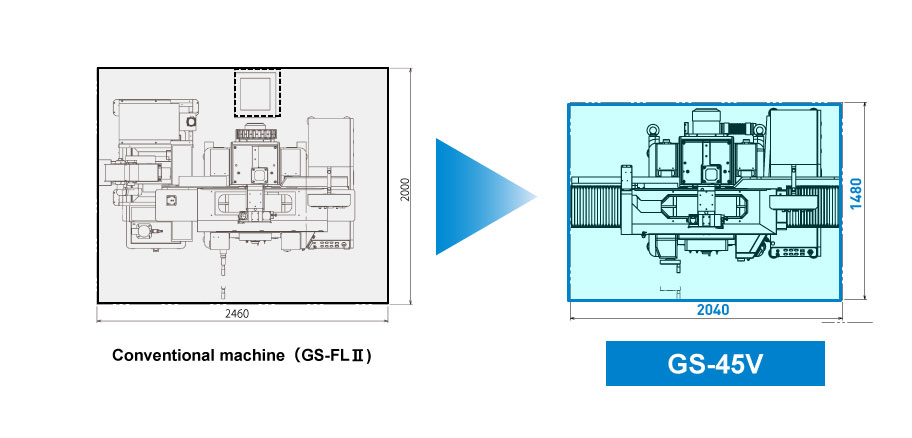

| Floor space required (W x L) | mm | 2040×1480 | ||

| Dimention of the machine (W x L x H) | mm | 2040x1280x1950 | ||

| Machine net weight | kg | 1600 | ||