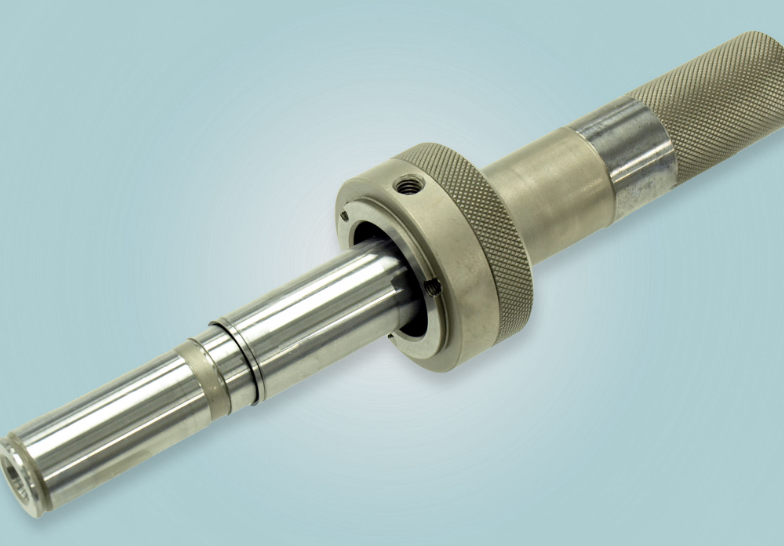

Hydraulic Tools for clamping thin-walled workpieces

KURODA's Hydraulic Tools utilize the elastic deformation of metal resulting from static hydraulic pressure to very precisely hold workpieces, even those having thin walls.

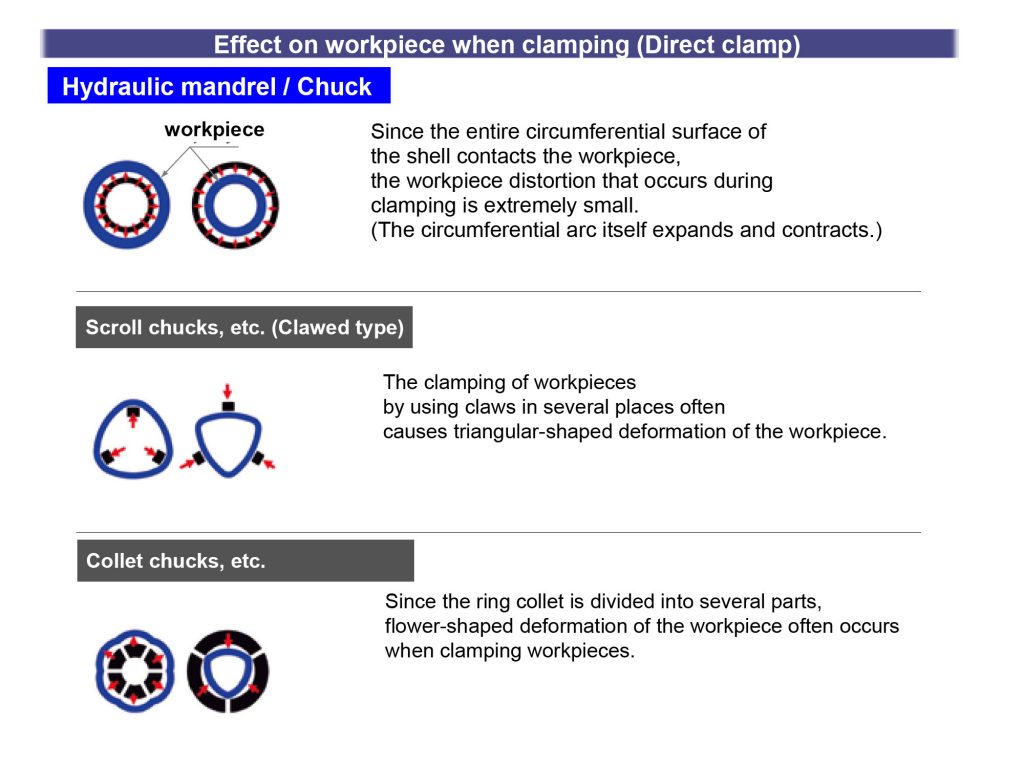

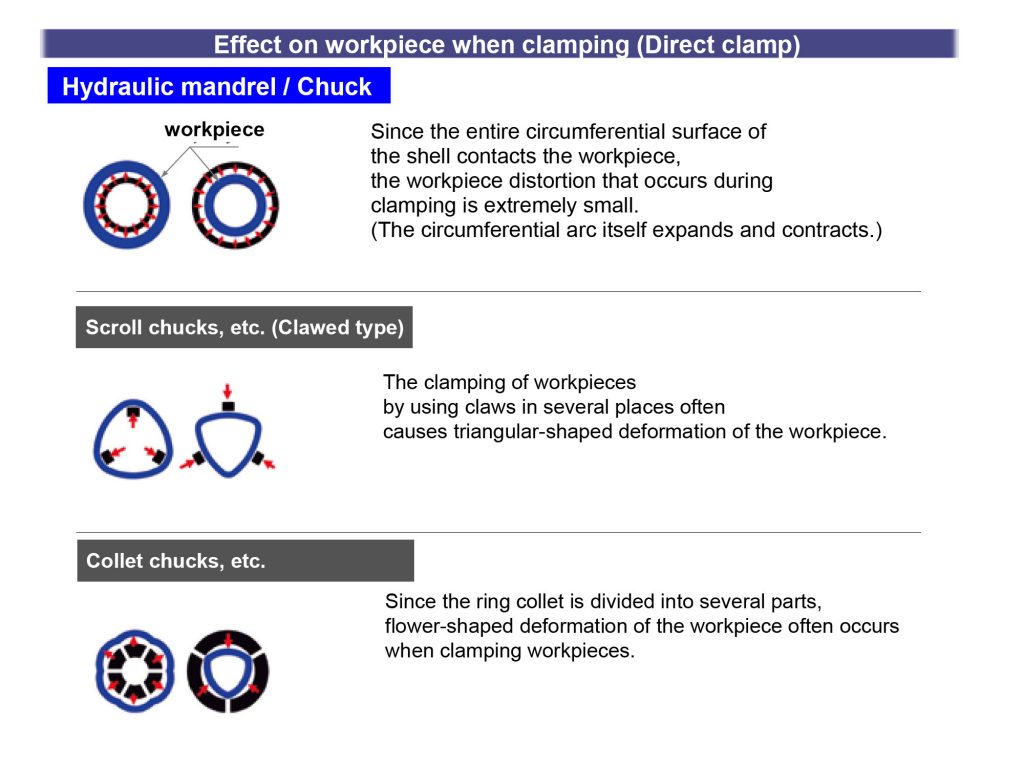

Holding workpieces with a uniform pressure

- Hydraulic Tools are jigs which very precisely clamp the round-shaped parts of workpieces.

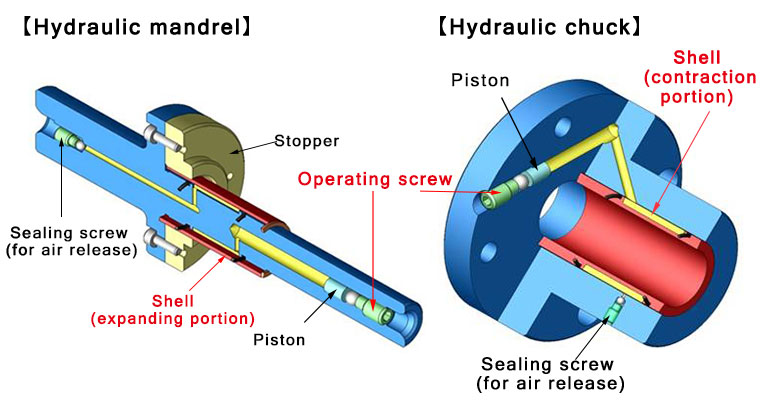

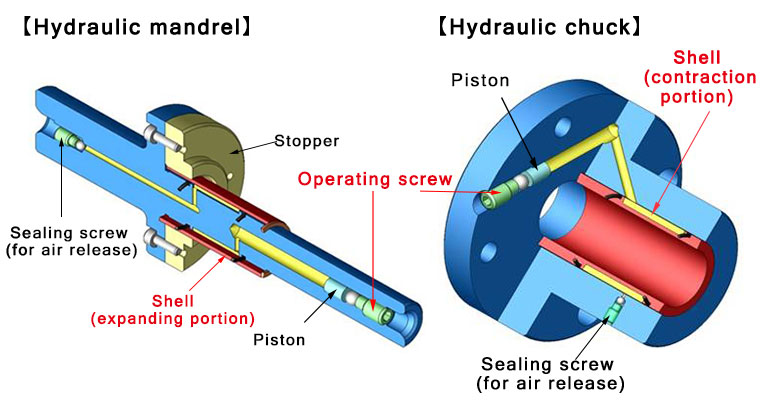

Utilizing the deformation of the metal in the thin-walled tubular parts resulting from static hydraulic pressure,

the round-shaped parts of workpieces are very precisely held.

- The oil sealed inside the Hydraulic Tool applies pressure equally to the shell according to Pascal’s principle, allowing highly precise clamping even of thin-walled workpieces.

Easy operation which does not require special skills

High precision clamping is possible using the easy operation of simply rotating a single operating screw.

Anyone can easily conduct the clamping, even when clamping thin-walled workpieces which normally require skilled operation.

Use in a variety of applications, from machining to assembly and inspections

Hydraulic Tools can be used in various situations to match customers’ applications.