Ultra-fine bubbles

By generating microbubbles (Ultra-fine bubbles) in a coolant, grindign efficiency is dramatically improved.

It solves the following problems:

- Shortening tact time

- Improving surface roughness; Reducing deviation of work pieces / Improving mirror finishing process and surface roughness

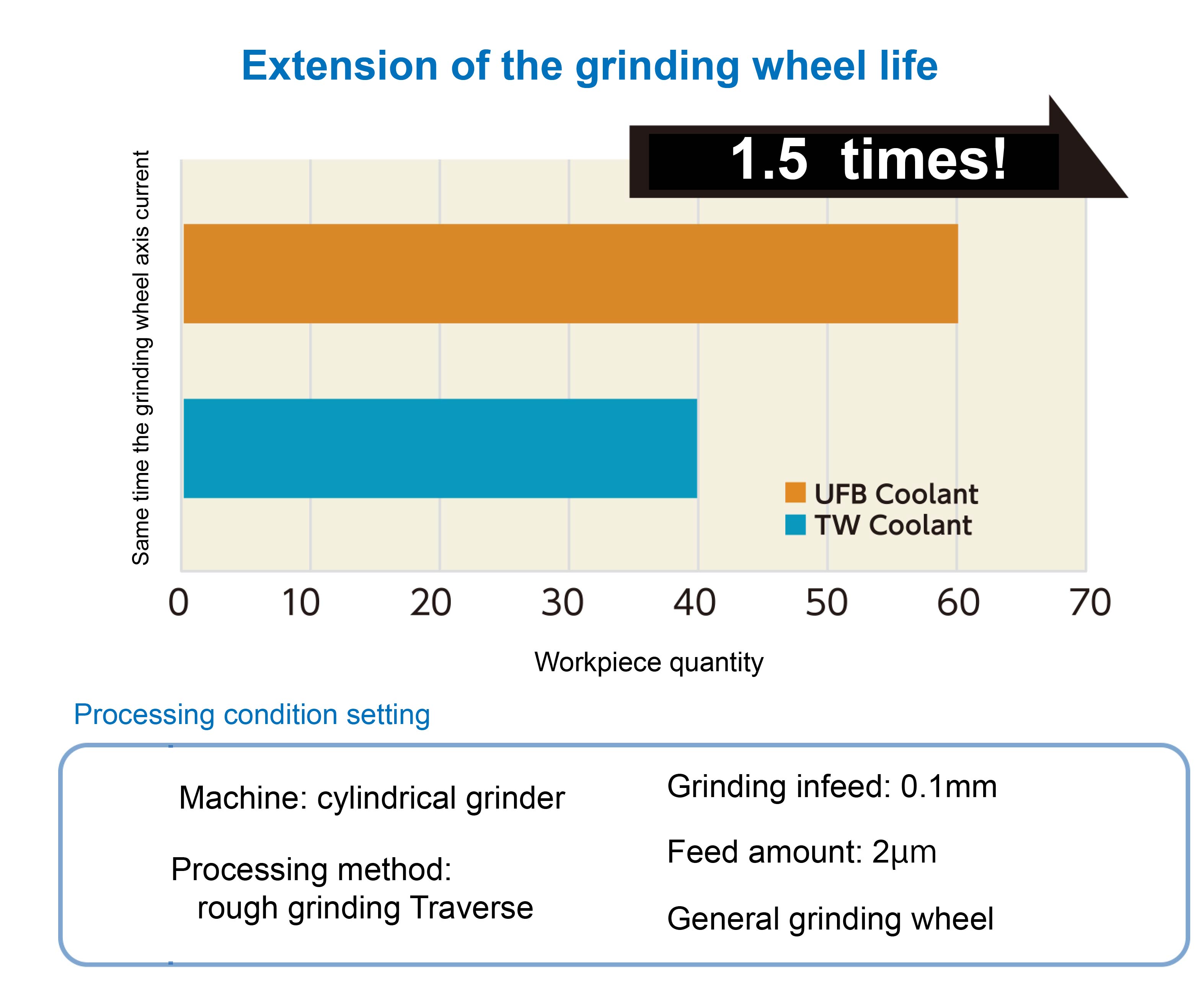

- Extending grinding wheel life

- Improving infeed of grinding

Features

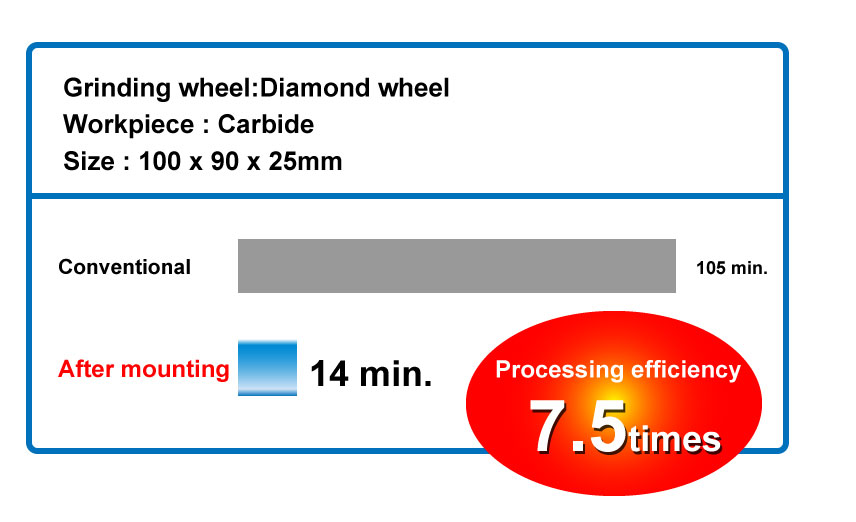

Significant expansion of processing efficiency

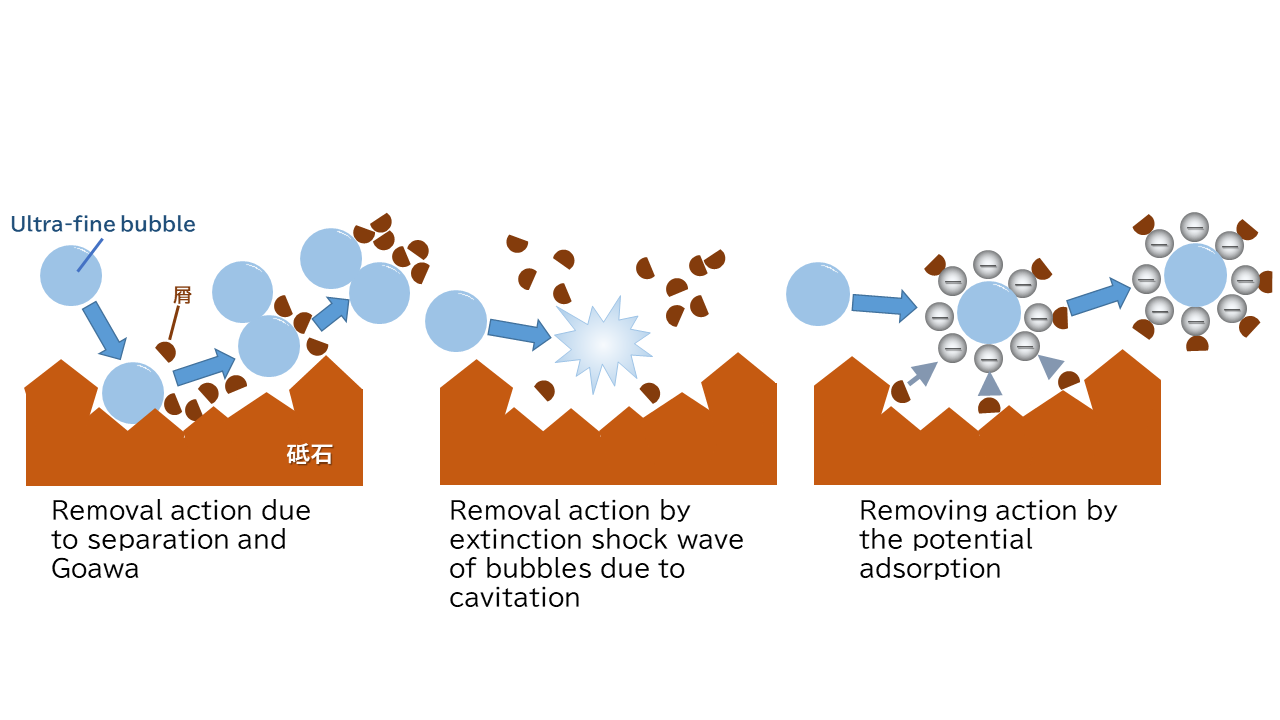

Bursted bubbles with high inner pressure (approx. 20 atm.) remove grinding chips of a grinding wheel by cavitation.

This physical action makes grinding wheels sustainably sharp. As a result, you can increase a grinding depth of a work piece.

Prevention of coolant corruption

Many aerobic bacteria are generated as a result of increase of the volume of oxygen in a coolant. It prevents an outbreak of injurious bacteria.

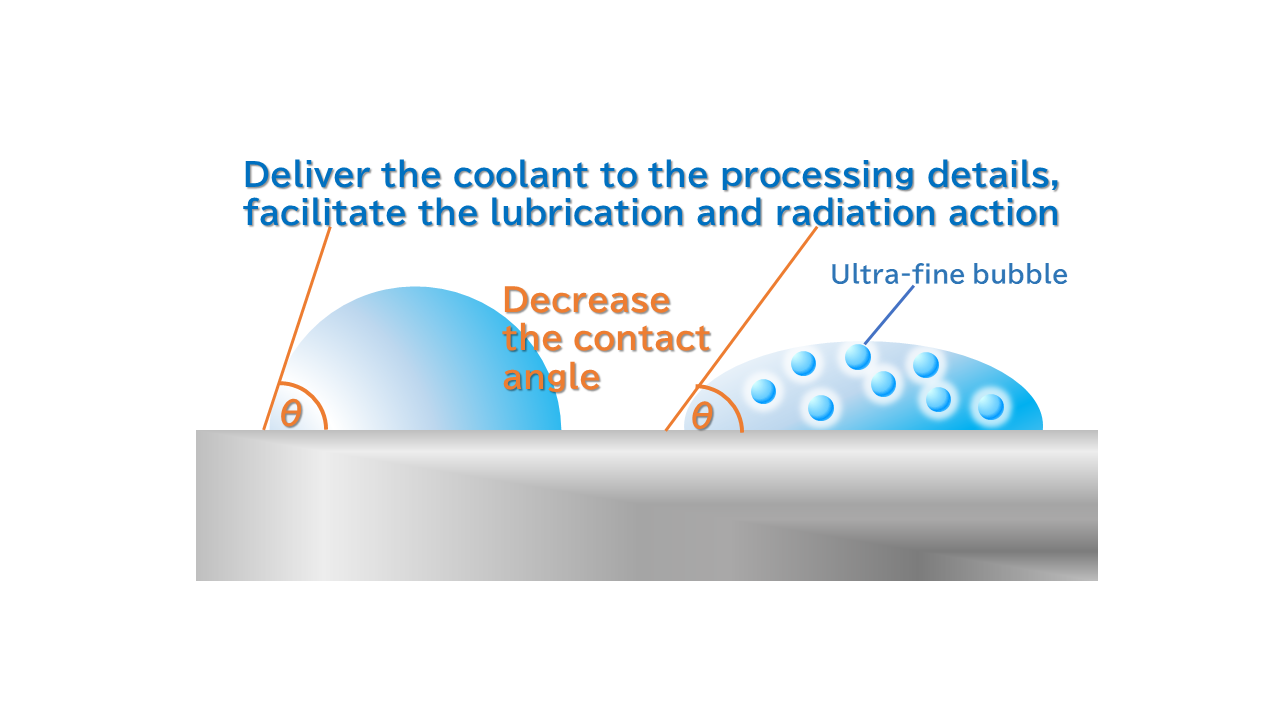

Improvement of dimensional accuracy

Due to the low grinding contact angle and the high wettability, you can easily reach a processing point on a work piece. Moreover, you can also expect cooling effect by the heat of vaporization during the burst of Ultra-fine bubbles. These effects lead to reduction of a heat stress and a distortion, and improve dimensional accuracy.

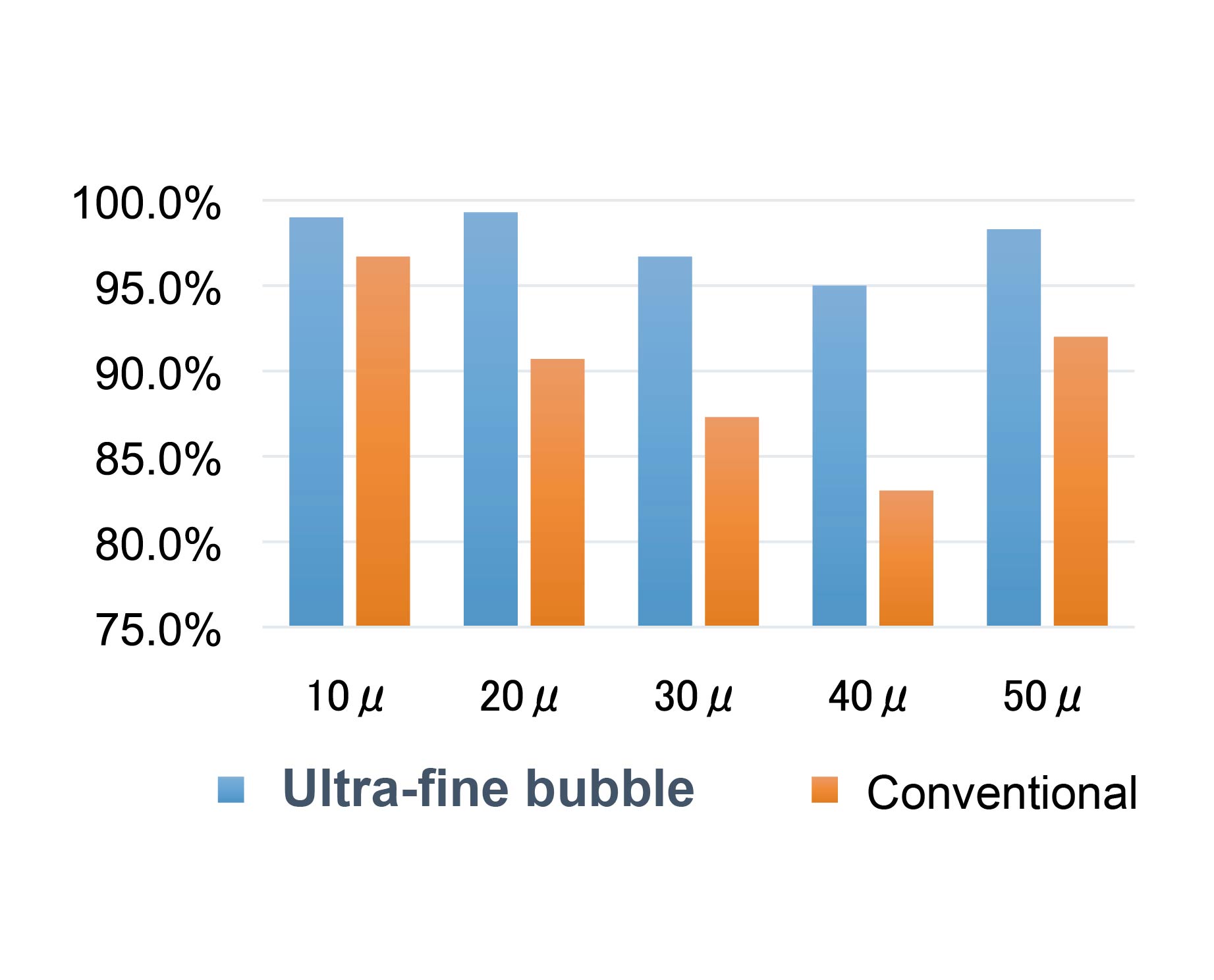

Life extension of grinding wheels

Sustainable sharpness of grinding wheels show dicrease of abrasive grain separation. This results lesser dressing frequency and long grinding wheel life.

Authorization by FBIA (Fine Bubble Industries Association in Japan)

This Ultra-fine bubbles device has been already authorized by FBIA. You can use this device in relief.