DNA of ”Precision”KURODA HISTORY90- DNA of ”Precision”: A history of craftsmanship passed on from one generation to the other -

Featured as a distinguished domestic manufacturer in the Journal of The Japan Society of Mechanical Engineers.

Developed and sold compact measuring instruments.

Built KURODA’s first surface grinding machine.

Became the first in Asia to receive the certification of compliance for reference master gauge from American Petroleum Institute (API).

Developed an electro-hydraulic pulse motor jointly with FUJITSU.

Launched the machine tools business.

Made full-scale expansion to ball screw and NC turning market.

Developed ”HADOMER”, an intermittent sequential pneumatic compressor.

Developed ”FASTEC®”, an in-die stacking system.

Developed a compact pneumatic control system.

Developed ”UNI-WIRE”, a wiring saving parallel/serial converter.

Started selling rolled ball screws.

Developed ”NANOMETRO®”, an ultra-precision surface shape measuring instrument for silicon wafers.

- Started selling motor cores for hybrid engines.

- Developed ”NANOMETRO® FTT”, a surface shape measuring instrument for large-scale liquid crystal photomask substrates.

Developed ”Glue FASTEC®”, an in-die automatic glue stacking system.

Started selling ball screws with resin nuts.

Kuroda Gauge Manufacturing Co., Ltd. was established. Promoted industrial production of interchangeable parts (American system) using gauges.

Developed and sold precision metal press dies for motor cores.

Became the first plant authorized to use the JIS mark.

Developed various measuring instruments such as the interference micrometre and large-scale screw measuring instrument (world’s first 3D measuring instrument).

Developed pneumatic equipment.

Developed a universal boring head.

Developed a nuclear power related measuring instrument.

- Started manufacturing and selling hydraulic equipment.

- Developed an electrical discharge machine.

Manufactured Japan’s first thread gauges for premium pipes.

Developed a magnetic head grinding machine.

Developed ”Super Polishing Machine”.

Developed ”Laser FASTEC®”, an in-die spot welding stacking system.

Developed ”ECOSAVER®”, a minimal quantity lubrication system.

Developed ”Next generation craftsman GS45 Series”, a precision forming surface grinding machine.

Developed ”NANOMETRO® 450TT”, an ultra-precision surface shape measuring instrument for silicon wafers up to Φ450 mm.

Started selling linear motion guides.

KURODA intends to keep true to its principles even beyond its 100th anniversary, continuing to contribute to the progress of the industrial society at large and the mutual development of customers, shareholders, community, personnel and company, as well as establishing ”Precision by KURODA” as a worldwide brand of quality and trust.

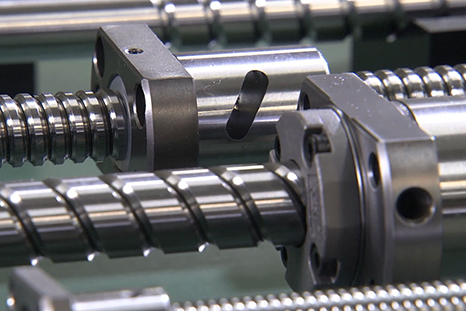

”Motion controls systems” are mechanical elements essential for machines to move accurately.

By leveraging the proven precision technology passed down in the company since its foundation and its global network, KURODA can not only provide various motion control system products including precision ground ball screws, but also offer solutions ranging from design of the motion control system product to manufacturing, sales, and after-sales services.

Hereafter, KURODA, with the aim of becoming a global brand of precision linear motion systems, will further work on its ability to provide solutions to add units and systems to its offering in order to respond to the needs of any industry with proven precision technology.

High-performance, silent motors capable of drawing the full potential of a product is a perpetual topic among manufacturers.

The ”FASTEC® system” dies, on which KURODA started working in the 1940s, are dies for ”motor cores”, that is, the heart of the motors. These dies allow for punching to rotation, stacking, measurement, and assembly inside the die, realizing accuracies on the order of microns and dramatic labour-savings in the manufacturing process.

By developing and proposing manufacturing methods that meet the needs of customers and those of the times, KURODA aims to become a global supplier of laminated cores for high-performance electric and electronic motors, as well as for the systems that manufacture them.

The ”Machine Tool & Measurement systems business”, combining KURODA’s core technologies of ”measurement” and ”grinding” into one, offers total support ranging from measurement to grinding by leveraging its comprehensive expertise.

KURODA will focus in the development of machining technology related to grinding, polishing, and measurement as only KURODA can, such as surface grinding machines which were first developed to manufacture its own dies; manufacturing of jigs for in-house use; and high value added grinding machines developed by combining measurement system with special jigs, in addition to supporting manufacturers all over the world.

Based on the mind that we will support the global precision technology tradition and development is the people, and since its inception, focuses on human resource development initiatives.

Human personel development initiatives can work and have a challenging, engages you and try to grow their own workplace, world stage can achieve our mission. See further initiatives "Personnel Development".